Why US

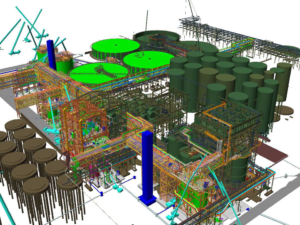

CRADLE TO GRAVE MODULARIZATION

fit-for-purpose

ModSmart has proven worldwide experience & will guide your capital development project. ModSmart will ensure fit for purpose by reviewing and accessing the following which include but not limited to :

- Design & engineering,

- Ensure critical inclusion are captured,

- Planning, Philosophy, Execution,

- Oversee module fabrication & assembly,

- Coordinate field construction, arrange module shipping and transportation,

- Assess module receiving terminals or material offloading facilities (MOF),

- Set up site staging area requirements, module dimensional control & positioning and hook up methodology.

Experience at scale

ModSmart will provide, true integrated solutions from conceptual modularization to module hook-up and commissioning.

Feasibility and Pre-FEL

To assess modularization feasibility.

fully Integrated solutions

FEL / FEED

ModSmart define module concepts and identify modularization value adds to the overall project.

Conceptual Engineering

Pre-Engineering design & initial concepts.

Module Yard Facilities

Plan and manage module fabrication and assembly.

Detailed Engineering

Guide engineering design with Modularization Know-How.

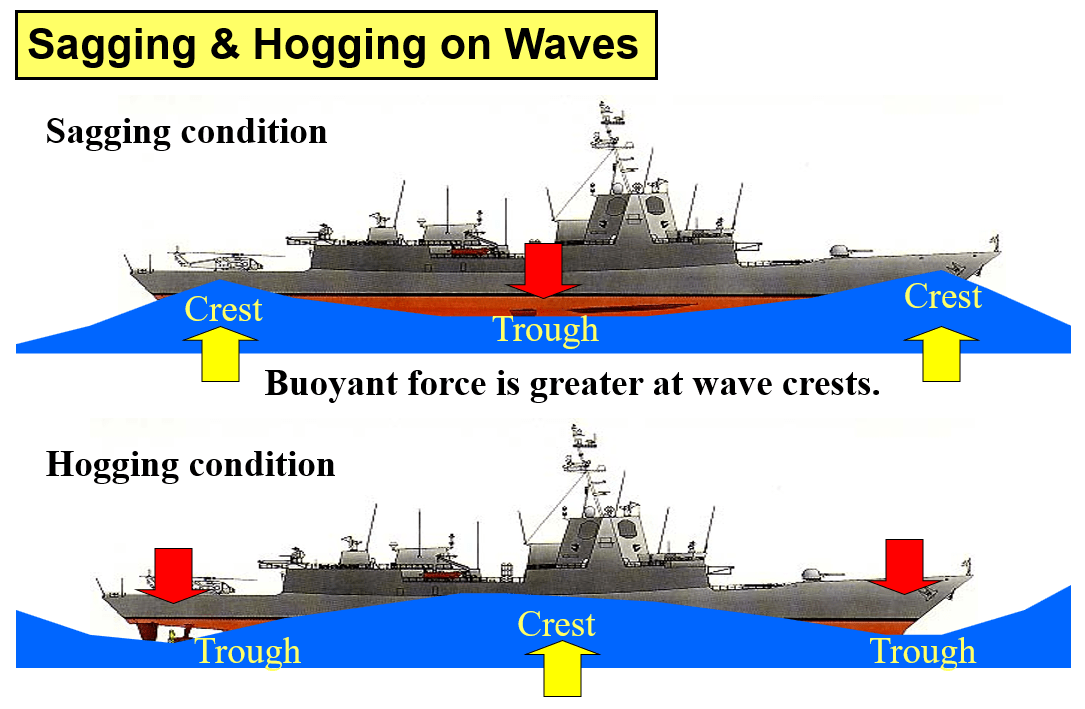

Land / Ocean Transportation

Assess vessel fleet requirements, truck, SPMT and other transportation constraints.

MOF, Receiving Terminal and Load-in & out

Compatibility Study and Assessment .

Module Integration

Integration management .

unbiased and neutral position

ModSmart takes a non-bias position to all stake holders in modularization programs, primary focus on Client’s interests and benefits including lowest TIC and certainty of delivery.